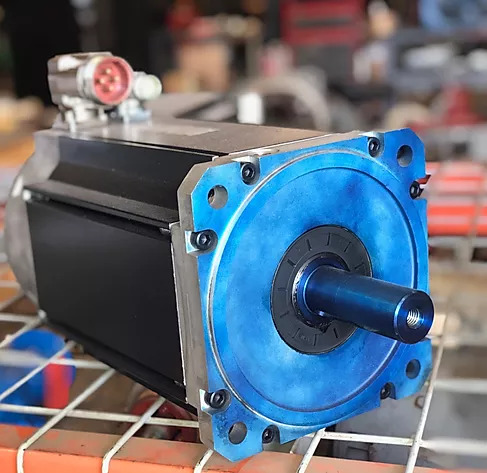

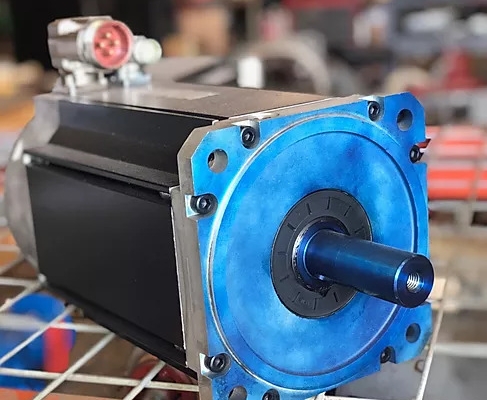

Servo Motor.

All servo motors are tested both statically and dynamically to insure proper operation. Encoders, resolvers, and tachometers are adjusted to correct the timing, waveform shape, offset position, voltage level, etc… Our rebuild process ensures that everything is reinstalled, properly sealed, repainted, and tested. All repairs are tested for quality assurance and must meet certain performance standards before leaving our facility. We maintain an extensive array of test equipment and offer complete run-testing and alignment of feedback devices to OEM specifications. Our software ensures that your feedback device is realigned correctly. We maintain the highest standard of quality control and take pride in our workmanship to guarantee that every motor is performing to its specifications.

IM&E can repair your servo motors as we repair all top name brands. We can replace bearings, rewind the stator, test the encoder, repair the brake, and confirm the integrity of the permanent magnets on the rotor. Our years of experience gives us an advantage over the competition. IM&E utilizes the latest technology of test equipment in our electronics shop, Mitchell analyzers and Pico oscilloscopes.