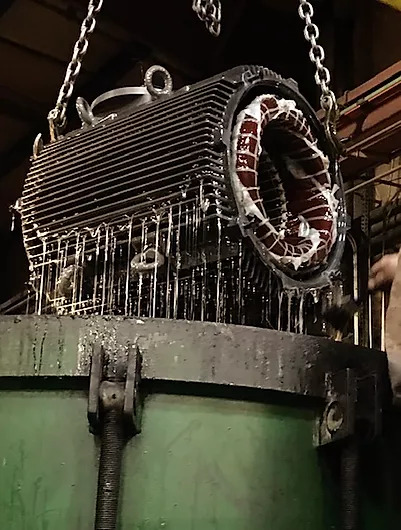

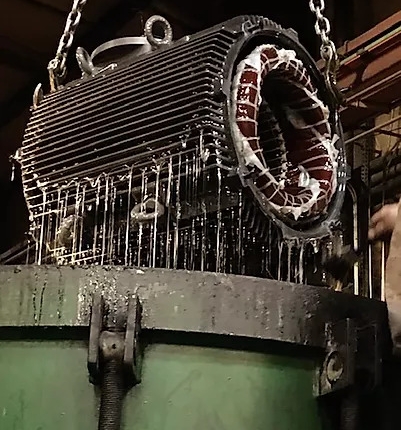

Winding.

IM&E can rewind all your low & medium voltage motors – our winding insulations & resins are class H rated (180°C) and are designed for voltages up to 7,200vac. We test every motor core both before and after burnout to ensure maximum efficiency is maintained during the rewind process (energy savings). If a motor is rewound by IM&E, it is uprated for use on a variable frequency drive. IM&E uses “Pulse Shield” magnet wire, making all our rewinds inverter ready. IM&E can provide a superior epoxy coating on the rewound stator with our vacuum pressure impregnation system (VPI) and our Epoxylite 478 Epoxy Resin – The 478 has an excellent field history and is the industry standard for use in the medium voltage power generation industry, Navy, and motor rewind market.